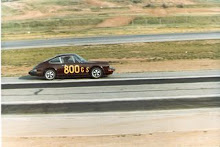

Another look at the back. Overall the RUF replica looks pretty clean.

Sunday, February 26, 2006

Posted by

David

at

9:31 PM

0

comments

![]()

The front bumper from the passenger side. Starting to look pretty good. Note that there are only two screws holding the unit on and none in the front so some sags are expected.

Posted by

David

at

9:29 PM

0

comments

![]()

A view from the driver's side. An Elephant Racing center mount oil cooler will fill the space in the middle of the valance.

Posted by

David

at

9:29 PM

0

comments

![]()

A shot of the mounted rear bumper. The tail lights are just dropped in to get a more finished look. Cutting the hole for the exhaust was a real pain. Working with the compound curves, angles and lack of reference points was a test of patience.

Posted by

David

at

9:29 PM

0

comments

![]()

Here's a look at the back of the car with the bumper and oil tank dropped. I'm getting pretty close to having enough engine auxillary components removed to pull it from the car. The only thing holding me back is that I am unsure I have enough vertical clearance with the current jack stand configuration.

Posted by

David

at

9:23 PM

0

comments

![]()

More glass fitting

Today I turned my attention to the front bumper. The unit sat about 3/4 inch forward on both sides. The first step was to get the basic shape of the under fender sections as close as possible. I thought that having them trimmed similarly would help keep the overall shaping consistent. The center section required the most work with a large step that needed to be fit to the trunk lip just past the rubber seal channel. With carful fitting I was able to get a good fit that neither pushes the section up nor allows it to sag. This section required some serious sanding of the back of the panel, as it was 1/4 inch or more too deep.

Where the fenders come down on either side of the hood I notched the glass. After a couple of hours of carefull fitting, cutting and sanding the front bumper is in place with a few set screws. There is still a fair amount of clean up to do where the indicators mount. That will be a challenge for another day.

Posted by

David

at

9:12 PM

0

comments

![]()

Yesterday, the 25th, I eased myself into the project as I was working off a wicked head cold. It took a while but I finally broke down and pulled the oil tank. It was in the way of getting the final fitting of the rear bumper completed. Pulling the tank wasn't too bad a job but dealing with the 30 years of caked on crud (oil and road dirt) was a pain. It's a good opportunity to clean up the tank and make sure it is properly sealed.

With the tank off fitting the bumper got a lot easier. When dealing with so many places to fit the fiberglass to the car it really pays to be cautious. I spent a fair amount of time deciding where to begin. The rear section, with the bumper and flares is far more complex then the front. I finally decided to line up the rear bumper where the tail light housing matches, get the sides and back as aligned as possible and get some set screws in place. I did this without the flares which will take a fair amount of fitting to get right. The bumper did line up well and is square overall. I did notice a discrepancy in the shape of the bumper between the left and right sides with the right being about a 1/4 inch wider as it blends into the flare. This does not appear to be a serious problem and it should be unnoticeable to anyone looking at the car.

Posted by

David

at

9:01 PM

0

comments

![]()

Thursday, February 23, 2006

Pictures and more pictures

What you see here is just a sample of the literally hundreds of pictures I’ve taken of this project to-date. If I’ve touched something on the car chances are I’ve taken at least a couple of pictures in the process. If you are interested in seeing something specific let me know. Keep in mind that I have been taking pictures while working on the car so I have predominately interior pictures, wiring, door assemblies, gauges, etc. I have fewer pictures of the engine and other mechanicals … so far.

Posted by

David

at

8:02 PM

0

comments

![]()

Here�s a look in the trunk and the mass of wiring that was either in the cabin or connected to the gauges and switches. This is going to be fun to reconnect when the car is going back together. I foresee long hours with the wiring diagram.

Posted by

David

at

7:59 PM

0

comments

![]()

It took a while but all of the gauges, switches and wiring has been removed from the cabin of the car. There is some work to be done around the bulkhead on the driver�s side but it is getting close to be stripped. I still need to remove the adhesive panels from the dashboard.

Posted by

David

at

7:57 PM

0

comments

![]()

This is a shot of a great looking 356 from a show in Dana Point. I think the car looks great and really like the color. The plan is to change the car from �the chocolate bar� to a silver bullet.

Posted by

David

at

7:46 PM

0

comments

![]()

A shot from behind with the new glass pieces, including SC flares, being test fit. Cut out for the exhaust is rough and it is going to take some time and effort to get everything lined up.

Posted by

David

at

7:44 PM

0

comments

![]()

Here is a shot with the front bumper removed. Both front and rear bumpers will be replaced with RUF CTR replicas from Rennspd.

Posted by

David

at

7:40 PM

0

comments

![]()

Finally got the dash top removed. This was no minor feat. It looks like it had been replaced before and that the last guy did it (or at least tried to do it) with the windshield in place. You can see where some water damage made it to the dash structure on the top left and (less visible) on the top right. The damage by the gauge seems odd.

Posted by

David

at

7:38 PM

0

comments

![]()

Next step in the tear down was removing the window and lock mechanisms from the doors. All of the exterior windows and rubber were also removed.

Posted by

David

at

7:35 PM

0

comments

![]()

Gauges were removed and ultimately the dash top is coming off. Plan is to replace it with a fiberglass unit. The lower portion of the dash panel, where the switches mount, is glued to the dash structure and will be removed with the help of a heat gun.

Posted by

David

at

7:34 PM

0

comments

![]()

Wednesday, February 22, 2006

Posted by

David

at

8:57 PM

0

comments

![]()

At this point I�ve decided to make the Porsche a replica-racer. I found a used Autopower roll bar from a local PCA member and prepped for the eventual installation. When done, the roll bar will be body color.

Posted by

David

at

8:55 PM

0

comments

![]()

Here�s a look at the rear seat area. Fortunately, even with some obvious water leaks from the window seals rust damage is minimal. You do learn a lot about a car when you tear it down to this level. It�s hard work that should pay off with the final product.

Posted by

David

at

8:52 PM

0

comments

![]()

Here�s a shot of some light rust at the seam of the tunnel and rear bulkhead. This would have never been found if the floor pan had not been completely stripped. Rust Mort was applied to all rust spots found. This transforms the rust, keeping it from spreading and provides a foundation for primer and paint.

Posted by

David

at

8:51 PM

0

comments

![]()

Tom after spending a few too many hours scrubbing the floor pan with lacquer thinner. It�s hard work but somebody�s gotta do it.

Posted by

David

at

8:49 PM

0

comments

![]()

The interior tear down begins. With the help of friend John and cousin Tom we got the floor pan stripped to metal in a matter of days.

Posted by

David

at

8:44 PM

0

comments

![]()

A look at that sweet horizontal six running with a new set of plugs and wires. Overall the compression is good: 150, 160, 160, 160, 160, 165. Not bad for a car that�s been parked since 1998.

Posted by

David

at

8:38 PM

0

comments

![]()

Posted by

David

at

8:36 PM

0

comments

![]()

Posted by

David

at

8:29 PM

0

comments

![]()

Here's Warren, the closest thing we have to a German car Master Technician, beaming with excitement at the start of another Porsche project.

Posted by

David

at

8:26 PM

0

comments

![]()

The project begins

At first the work on the Porsche was haphazard.

Really what pushed me into this decision was when my wife came home and said I needed to go “scrape the giant turd off the driveway.” It’s hard to blame her given the condition of the paint (70’s brown at its ‘finest’ with a mix of grey and black primers). I figured a shiny paint job would surely change the reaction to the car, and we all know how important first impressions are.

Here’s where the real project begins.

Posted by

David

at

7:52 PM

0

comments

![]()